Everton FC

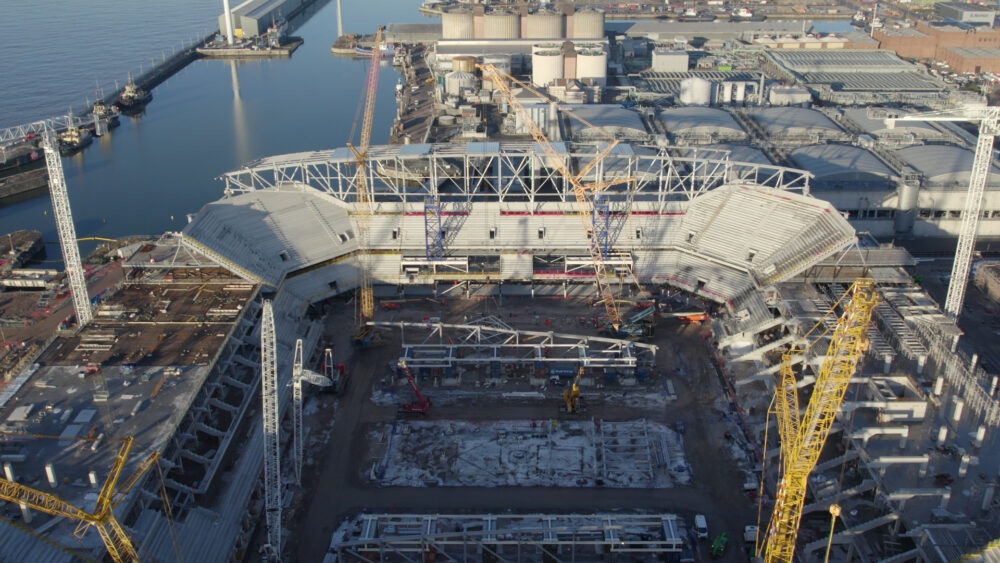

Find out about the detailed planning on the ground that helps to build the Everton Stadium so efficiently

3 years ago

As work hits the heights at Everton Stadium, it’s the painstaking work done on the ground that ensures everything continues to go to plan.

The relentless daily deliveries of all materials and components to the Everton Stadium at Bramley-Moore Dock provides a huge scheduling challenge for the logistics team at Laing O’Rourke.

However, the ‘just-in-time’ delivery programme – the result of three years of meticulous planning and an essential part of the construction partner’s pioneering approach called Design for Manufacturing and Assembly (DfMA) – is paying dividends as the team celebrates a calendar year that has seen the stadium develop at impressive speed.

“We have designed this stadium with assembly in mind, rather than construction, which is a more modern way of constructing buildings,” explained Ben Townsley, Civil and Structures Project Leader at Laing O’Rourke.

“What that means is that we have a huge number of products, materials and components that we need to bring onto the site and assemble, in order, to construct the project properly.

“The term ’just-in-time’ is used across the manufacturing industry and that basically involves getting all those products to the right place at the right time.

“With all of these different deliveries coming in through the gate, we can’t end up with a backlog and wagons queuing up down the street, annoying our neighbours, so we try to allocate a two-hour window for every delivery.

“The aim is that those components then come through the gate and, within two hours, are offloaded, installed, and the wagon leaves.

“We can have 60-80 deliveries a day and that’s the art of construction. Every component that we have to build and install has a different length of installation time, so we have to plan each delivery meticulously to attempt to make it fit within that finite window, or we would end up in chaos.”

The sheer scale of that complex planning operation becomes apparent when you delve into the figures.

Approximately 20,000 delivery slots for wagons were scheduled in 2022, carrying around 7,300 precast concrete components, over 6,000 steel components and 3,000 tonnes of reinforced steel from roads across the UK and Europe.

The 2,010 bespoke, double-stepped terracing units which will form the internal bowl lining have also crossed the Irish Sea, having been manufactured in Ireland by Laing O’Rourke’s supply chain partner, Banagher and delivered by boat to Liverpool docks, a short distance from the project site.

During the past year, 27,613 cubic metres of in-situ concrete was delivered to the Everton Stadium site, via in excess of 3,500 mixing wagons, and poured across all four sides of the stadium to provide the reinforced floors and ceilings.

Add in over a quarter of a million nuts and bolts, drainage material, aggregates and plant equipment, and the team responsible for logistics are most definitely kept busy while assembling the Everton Stadium.

“I’ve stood in the building in a 3D environment and we’ve been looking at the design of this stadium now for three years,” added Townsley

“When we first started looking at this project, we sat down and decided on which days each product would come into site.

“We plan very far in advance, but you can imagine that a lot can change in the subsequent three years and we have to deal with that, all the way up to the point of installation.

“The wind may start blowing, the temperature may change and all these things can affect some of the deliveries.

“So we plan our deliveries meticulously as far as we can, up to two weeks in advance, but then every hour of the day we monitor that, moving wagons around and speaking to some of the delivery drivers to delay them, or bring them forward slightly.

“We have a huge logistics team and it’s all about team work. Without them pulling together and monitoring all those deliveries, we wouldn’t be where we are today.”

Subscribe

Subscribe Follow Us

Follow Us Follow Us

Follow Us Follow Us

Follow Us Follow Us

Follow Us Follow Us

Follow Us